We guarantee a lasting impression.

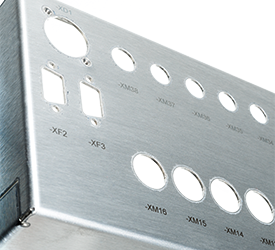

Laser marking.

- Annealing laser marking and engraving from a font size of 0.5 mm

- Line widths from 40 µm

- Data matrix in 2D and 3D

- Circumferential marking on pipes up to approx. 200 mm in diameter

- Materials such as stainless steel, anodised aluminium, brass, copper, titanium, burnished steels, colour removal, laser-endowed plastics, etc.

- Max. dimensions of 1,200 x 400 x 400 mm, piece weight up to 50 kg

Our lasermarking department marks your components durably and to a defined depth or as annealing colours in metal, selected plastics and ceramics.

The spectrum stretches from the 0.5 mm high number through to large-size machine systems in a marking space of up to 1,200 x 400 x 400 mm using a stitching procedure.

In the field of laser material machining, we manufacture individual pieces as well as large series. Quality and short delivery times are an important aspect for laser marking. With two laser marking systems, we are well prepared for large capacities.

In laser inscribing, the surface of the workpiece is directly marked with the laser through colouring or engraving, without touching the workpiece.

Key benefits: High quality and marking speed as well as high durability. Laser marking is also suitable for hard to reach areas and micro-labeling.

We are able to work with all steel and stainless steels, non-ferrous metals, different alloys and technical ceramics (aluminium oxide, silicon nitride, boron nitride).