Laser cutting system for operation with different working gases

This was the job:

Development and manufacturing of a compact laser cutting system for the multi-dimensional processing of rupture discs and similar components. Dome-shaped contours were to be executed in a machining area of 500 x 500 x 300 mm. Laser fine cuts were to be carried out in pulsed fashion with different working gases.

This is how we solved it:

A pulsed QCW fibre laser with 150 W average power and 1500 pulse power as well as the best beam quality (single-mode optical fibre, TEM00) was selected as the laser source. Processing optics with capacitive distance sensors were used to ensure that the nozzle distance to the surface is maintained, even when components are cut to size. The axes were equipped with linear motors or torque motors to ensure high dynamics and freedom from wear.

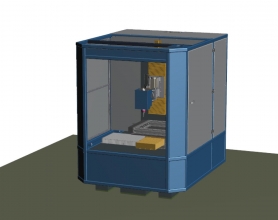

The protective cabin supported by the granite foundation was provided with a very large service door despite its compact dimensions. This was designed as a motorised sectional door with generous protective glazing.

The side walls of the cabin can also be opened for easy access and, with their protective glasses, contribute to the transparent appearance of the entire machine.

The control electronics, a CNC control of the latest Fanuc generation, as well as the IPG fibre laser, were fully integrated in the back of the machine. For the programme-controlled selection of gas type and gas pressure, a switching device from Hoerbiger was used. In the CNC programme, the gas type and pressure can be selected as required and changed during the machining process.

The result:

Transparent appearance, state-of-the-art drive and laser technology. Linear motor drive, QCW fibre laser, granite and CNC technology from the market leader.

Customer:

Schlesinger GmbH